Custom Screen Printing

Precision Imprint utilizes genuine screen printing. Screen printing, also known as silk screening, is the process of pushing specialized ink through a mesh screen to print custom artwork or logos onto apparel & accessories.

We think it is beneficial for our customers to have a basic understanding of the screen printing process and the time and attention that is given to each custom order. Below, we will take you through the steps utilized when creating your custom screen-printed apparel and accessories at Precision Imprint.

We think it is beneficial for our customers to have a basic understanding of the screen printing process and the time and attention that is given to each custom order. Below, we will take you through the steps utilized when creating your custom screen-printed apparel and accessories at Precision Imprint.

|

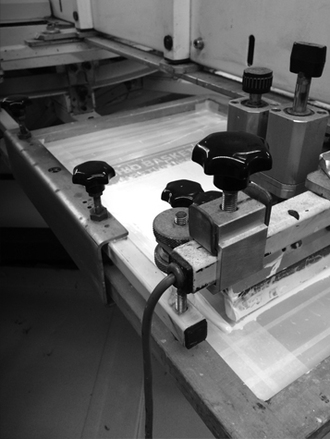

Step 2: Screen Preparation And ExposureYour artwork is then sent to our set-up area where it is registered and checked for quality. Once it passes inspection, it's ready to go on a screen.

We use a variety of screens at Precision Imprint. The type of screen we use is dependant on the type of job being printed. There are different sizes of mesh used in screen printing. The appropriate mesh is determined by the detail in the artwork to be printed. When more fine detail is present in custom art a higher mesh count is required. After the proper screen is chosen, it must be coated with a photosensitive emulsion and placed in a drying cabinet. Once the emulsion has dried, the color separated vellum printouts are taped to screens. Each screen is then placed on to the exposure table where ultraviolet light will expose the emulsion that is not being blocked by the art on the vellum. The screens are then transferred to the wash out tub, where they are sprayed with pressurized water. The emulsion that was not exposed will wash out, creating your art on the screen. Each screen is then checked against the original art files for accuracy. |

|